On-site density calibration: Our patent-pending process

Calibration during operation – save time and reduce plant shutdowns

In the past, density measuring devices such as Coriolis or vibronic measurement technology could only be sent to the manufacturer's factory for calibration. This involved considerable costs and required the plant to be shut down. It is now possible to calibrate measuring devices on-site, in your own plants. Endress+Hauser is the only provider of a patent-pending procedure for on-site density calibration.

Benefits

Patent-pending mobile equipment developed in-house for on-site density calibration guarantees high product quality for you

Calibration during operation saves time and reduces plant shutdowns

Realistic calibration under real process conditions increases the reliability of the calibration

Non-proprietary density calibration reduces the coordination required

Maximum quality thanks to experienced calibration engineers trained specifically for this industry

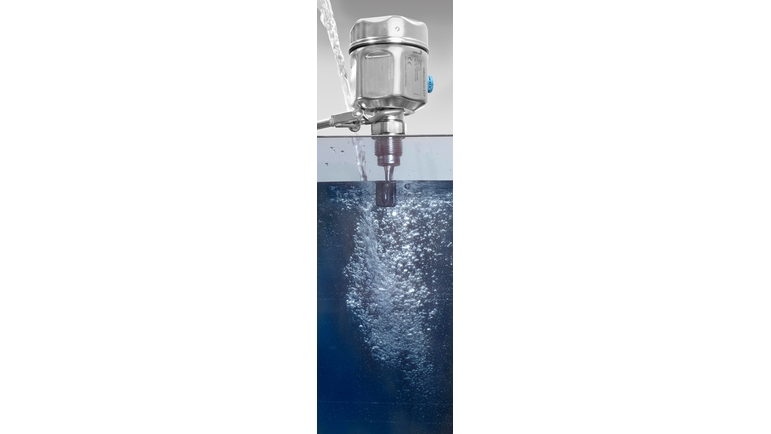

Endress+Hauser is the only provider of a patent-pending procedure for on-site density calibration, for example of Promass density measuring devices. Traceable calibration takes place offline in this case. This means that you benefit from on-site calibration under real process conditions. This makes it possible to check density measuring devices (Coriolis, vibronic measurement technology with density function) simply and cost-effectively, and to comply with regulations and standards effortlessly.

Unique and traceable

To ensure a high level of measuring accuracy, measuring devices must be calibrated in environments which are as realistic as possible. For this reason, the calibration service team uses mobile equipment developed by Endress+Hauser with Promass F (special density calibrated) as a high-precision reference device during on-site density calibration. This involves performing calibration under real temperatures and pressures.

Highly accurate density calibration under process conditions

Coriolis density measuring devices (DN08-DN50) and vibronic density measuring devices can be calibrated on-site with different densities (0.998 g/cm3 to 1.20 g/cm3) to an accuracy of 0.3% of the measured value. Accordingly, calibration points can be selected individually. You can benefit from the most accurate density measurement under real-life process conditions. This service can be used for any density measuring devices, not just Endress+Hauser (Liquiphant Density and Promass).

Service at the optimal time

Calibration in the plant itself makes removing and sending in the device unnecessary. At the same time, it ensures that the device is tested at the installation site and under the prevailing operating conditions. In addition, the on-site calibration can be directly linked with any necessary adjustment, repair or device replacement, and other maintenance work. You set the timings for the calibration yourself, so that your plants are always calibrated at the right time.

Non-proprietary calibration of all measured variables

In addition, we offer you comprehensive support with our calibration service accredited in accordance with ISO/IEC 17025 for virtually all physical, analytical and mechanical parameters customary in the process industry.

This ensures optimum performance for minimum costs – and all this with only one contact for all measured variables.

Downloads

-

MEGGLE setzt auf die Expertise von Endress+Hauser

Korrekte Abrechung und Qualität gesichert - MEGGLE setzt auf die Expertise von Endress+Hauser

File size:

File name:

-

Einzigartige Kalibrierkompetenz (CP01102H)

Qualitätsstandards sichern und Kalibrierprozesse optimieren

File size:

File name: