%20with%20flange%20connections%20for%20accurate%20measurement%20of%20natural%20and%20process%20gas%20-%20PP01.jpg)

Specs at a glance

-

Max. measurement error

Volume flow (standard):

‐ ±1.0 % o.r. for 3 to 40 m/s (9.84 to 131.23 ft/s)

‐ ±2 % o.r. for 0.3 to 3 m/s (0.98 to 9.84 ft/s)

Volume flow (optional calibration):

‐ ±0.5 % o.r. for 3 to 40 m/s (9.84 to 131.23 ft/s)

‐ ±1.0 % o.r. for 0.3 to 3 m/s (0.98 to 9.84 ft/s)

Corrected volume flow (standard):

‐ ±1.5 % o.r. for 3 to 40 m/s (9.84 to 131.23 ft/s)

‐ ±2.5 % o.r. for 0.3 to 3 m/s (0.98 to 9.84 ft/s)

Corrected volume flow (optional calibration):

‐ ±1.0 % o.r. for 3 to 40 m/s (9.84 to 131.23 ft/s)

‐ ±1.5 % o.r. for 0.3 to 3 m/s (0.98 to 9.84 ft/s)

Sound Velocity: ±0.2 % o.r. -

Measuring range

Gas: 0.3 m/s to 40 m/s

-

Medium temperature range

-50 to 150 °C (-58 to +302°F)

-50 to 100 °C (-58 to +212°F) with integrated pressure cell -

Max. process pressure

0.7 to 101 bar a (10.15 to 1464.88 psi a)

-

Wetted materials

Measuring tube: 1.4408/1.4409 (CF3M)

Transducer: 1.4404 (316, 316L, Titan Grade 2

Field of application

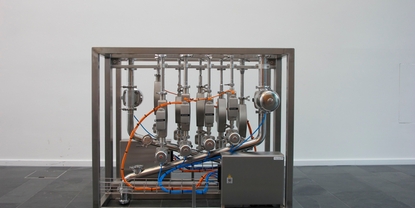

For a wide range of gas applications Prosonic Flow G provides reliable flow measurement, even with wet gas and changing gas properties and compositions. A pressure-rated sensor housing with rupture disc limits safety risks. The innovative remote transmitter maximizes installation flexibility and operational safety in demanding environments. Heartbeat Technology ensures compliance and process safety at all times.

The measuring principle is unaffected by gas composition

Accurate measurement of natural and process gas in the chemical as well as oil and gas industries.

Device properties:

Direct measurement: flow, pressure & temperature

Wetted parts: titanium / 316L

Maximum measuring accuracy: 0.5 %

Remote version with up to 4 I/Os

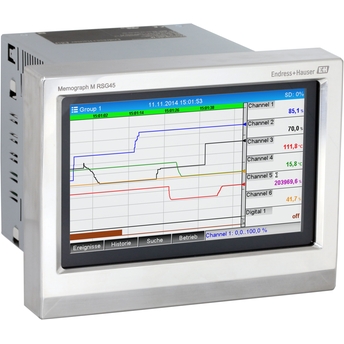

Backlit display with touch control and WLAN access

Standard cable between sensor and transmitter

Benefits

Flexible device with user-definable gas mixtures for demanding measuring tasks

Maximum reliability even with humid or wet gas – sensor design insensitive to condensate

High-performance process control – real-time pressure- and temperature-compensated values

Efficient solution – multivariable, no pressure loss

Full access to process and diagnostic information – numerous, freely combinable I/Os

Reduced complexity and variety – freely configurable I/O functionality

Integrated verification – Heartbeat Technology

Videos

Extended selection

-

High-end products

- Highly functional and convenient

Technical excellence

Simplicity

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

-

-

Operating Instruction (BA)

BA Proline Prosonic Flow G 500

English version - 01/2024

Ultrasonic time-of-flight flowmeter HART

EN 31/01/202416/09/201905/08/2019Language:

English

Version:

31/01/2024

File size:

7.9 MB

File name:

BA01836DEN_0324-00.pdf

-

-

-

Technical Information (TI)

TI Proline Prosonic Flow G 500

English version - 01/2024

Ultrasonic time-of-flight flowmeter

EN 31/01/202416/09/201905/08/2019Language:

English

Version:

31/01/2024

File size:

6.1 MB

File name:

TI01386DEN_0324-00.pdf

-

-

-

Technical Information (TI)

TI Proline Prosonic Flow G 500

Ultrasonic time-of-flight flowmeter

EN 31/01/202416/09/201905/08/2019Language:

English

Version:

31/01/2024

File size:

6.1 MB

File name:

TI01386DEN_0324-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Prosonic Flow G 500

Ultrasonic time-of-flight flowmeter

HARTEN 31/01/202416/09/201905/08/2019Language:

English

Version:

31/01/2024

File size:

7.9 MB

File name:

BA01836DEN_0324-00.pdf

-

-

-

Operating Instruction (BA)

BA Proline Prosonic Flow G 500

Ultrasonic time-of-flight flowmeter

Modbus RS485EN 31/01/202416/09/201905/08/2019Language:

English

Version:

31/01/2024

File size:

7.3 MB

File name:

BA01837DEN_0324-00.pdf

-

-

-

Device Parameter (GP)

GP Proline Prosonic Flow G 500

Ultrasonic time-of-flight flowmeter

HARTEN 31/01/202405/08/2019Language:

English

Version:

31/01/2024

File size:

2.4 MB

File name:

GP01132DEN_0224-00.pdf

-

-

-

Device Parameter (GP)

GP Proline Prosonic Flow G 500

Ultrasonic time-of-flight flowmeter

Modbus RS485EN 31/01/202405/08/2019Language:

English

Version:

31/01/2024

File size:

2.8 MB

File name:

GP01133DEN_0224-00.pdf

-

-

-

Short Instruction (KA)

KA Proline 500 – digital

HART transmitter

with ultrasonic time-of-flight sensorEN 31/01/202405/08/2019Language:

English

Version:

31/01/2024

File size:

1.3 MB

File name:

KA01377DEN_0224-00.pdf

-

-

-

Short Instruction (KA)

KA Proline 500 – digital

Modbus RS485 transmitter

with ultrasonic time-of-flight sensorEN 31/01/202405/08/2019Language:

English

Version:

31/01/2024

File size:

1.7 MB

File name:

KA01378DEN_0224-00.pdf

-

-

-

Short Instruction (KA)

KA Flowmeter Proline Prosonic Flow G

Ultrasonic time-of-flight sensor

EN 31/01/202405/08/2019Language:

English

Version:

31/01/2024

File size:

949.1 KB

File name:

KA01374DEN_0224-00.pdf

-

-

-

Installation Instructions (EA)

EA Replacing the sensor, gasket for sensor and the pressure cell

Prosonic Flow G 300, 500-digital

EN 15/03/202402/08/202215/02/202101/04/202030/09/2019Language:

English

Version:

15/03/2024

File size:

767.1 KB

File name:

EA01254DA2_0624-00.pdf

-

-

-

Installation Instructions (EA)

EA Replacing Small Parts

Proline 10, 400, 500, 500-digital, 800 Index B, 800 Index C, Cubemass

EN 01/01/202415/12/202101/05/202101/04/202101/06/2020Language:

English

Version:

01/01/2024

File size:

1.2 MB

File name:

EA01024DA2_1223-00.pdf

-

-

-

Installation Instructions (EA)

EA Replacing the Components for the Transmitter

Proline 400, 800 Index C, 500-digital

EN 01/01/202415/12/202101/11/202101/04/202101/06/2020Language:

English

Version:

01/01/2024

File size:

2 MB

File name:

EA01094DA2_1223-00.pdf

-

-

-

Installation Instructions (EA)

EA Alteration Display module to Display module with WLAN

Proline 300, 400, 500, 500-digital

EN 01/01/202401/08/202131/07/202002/08/201902/01/2019Language:

English

Version:

01/01/2024

File size:

1.4 MB

File name:

EA01158DA2_0823-00.pdf

-

-

-

Installation Instructions (EA)

EA Replacing Small parts

Proline 10, 100, 400, 800 Index C, 500, 500-digital, CNG-, LNG-, LPGmass

EN 01/01/202401/05/202101/04/202131/07/202002/08/2019Language:

English

Version:

01/01/2024

File size:

518.1 KB

File name:

EA01119DA2_0923-00.pdf

-

-

-

Installation Instructions (EA)

EA Replacing the Display Protection

Proline 400, 800 Index C, 500-digital

EN 01/01/202415/12/202101/06/202002/08/201901/03/2018Language:

English

Version:

01/01/2024

File size:

480 KB

File name:

EA01093DA2_0723-00.pdf

-

-

-

Installation Instructions (EA)

EA Replacing the electronics

Proline 300, 500, 500-digital

EN 01/01/202401/07/202301/06/202131/07/202002/08/2019Language:

English

Version:

01/01/2024

File size:

1.6 MB

File name:

EA01145DA2_0823-00.pdf

-

-

-

Installation Instructions (EA)

EA Protective Cover connection compartment

Proline 300, 500, 500-digital

EN 01/01/202401/06/202301/06/202131/07/202002/08/2019Language:

English

Version:

01/01/2024

File size:

6.2 MB

File name:

EA01146DA2_0823-00.pdf

-

-

-

Installation Instructions (EA)

Replacing the transmitter Installation Instructions

Prosonic Flow 500-digital

EN 05/08/2019Language:

English

Version:

05/08/2019

File size:

324.5 KB

File name:

EA01264DA2_0119.pdf

-

-

-

Installation Instructions (EA)

EA Pipe mounting set

Proline 400, 500-digital

EN 01/01/202415/12/202131/07/202002/08/201901/02/2017Language:

English

Version:

01/01/2024

File size:

518.8 KB

File name:

EA01195DA2_0523-00.pdf

-

-

-

Installation Instructions (EA)

EA Replacing the display module

Proline 300, 500, 500-digital, DKX001–

EN 01/01/202401/06/202131/07/202002/08/201902/01/2019Language:

English

Version:

01/01/2024

File size:

712.8 KB

File name:

EA01144DA2_0723-00.pdf

-

-

-

Installation Instructions (EA)

Replacing cover, O-ring, seal housing for transmitter wall mounting and seal housing for the sensor side

Promag 10, Promag, Promass, Prosonic Flow 500, 500-digital, t-mass

500-digitalEN 01/06/202101/05/202131/07/202002/08/201915/09/2018Language:

English

Version:

01/06/2021

File size:

1.2 MB

File name:

EA01162DA2_0621.pdf

-

%20with%20flange%20connections%20for%20accurate%20measurement%20of%20natural%20and%20process%20gas%20-%20PP01.jpg)

.jpg)