Specs at a glance

-

Max. measurement error

Flow: ±5 % o.f.s.

-

Measuring range

226 to 14 100 000 l/h (60 to 3 730 000 gal/h)

(under reference conditions) -

Medium temperature range

–20 to +100 °C (–4 to +212 °F)

-

Max. process pressure

PN 40

-

Wetted materials

Transducer: 1.4404 (316/316L); Alloy C22, 2.4602 (UNS N06022)

Insertion tube: 1.4404 (316/316L); Alloy C22, 2.4602 (UNS N06022)

Connection:

‐ Compression fitting: 1.4404 (316L); Alloy C22, 2.4602 (UNS N06022)

‐ Threadolet: 1.4404 (316L); Alloy C22, 2.4602 (UNS N06022)

‐ Clamping ferrule: PEEK 450G; 1.4404 (316L); Alloy C22, 2.4602 (UNS N06022)

‐ Tri‐Clamp; DN40 DIN 11851, DN50 DIN 11851; DN40 DIN 11864‐1A, DN50 DIN 11864‐1A: 1.4404 (316L)

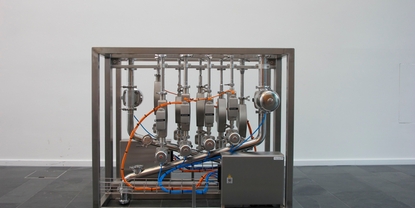

Field of application

The t-mass T 150 is the first thermal mass device from Endress+Hauser for measuring liquids. t-mass T 150 is designed chiefly for water applications. As it measures independently of the electrical conductivity of a fluid and can be used in a variety of water-based and non-water-based liquids for the purpose of monitoring and trending. Customer-specific settings are saved on the display and can be transferred from one device to another by means of the display.

Measuring principle is characterized by a high operable flow range and direct mass flow measurement

Dedicated to the monitoring of conductive and non-conductive liquids.

Device properties

Insertion version for nominal diameter DN 40 to 1000 (1 1/2 to 40")

Sensor in standard or hygienic version

SIP cleaning possible up to 130 °C (266 °F)

Device in compact version with DC 24 V power supply

4-20 mA HART, pulse/frequency/switch output

Compact and robust transmitter

Benefits

Dedicated to the monitoring of conductive and non-conductive liquids

High process safety – high repeatability and linearity due to integrated temperature compensation

Cost-effective measurement – easy installation, negligible pressure loss and maintenance-free

Reliable flow trending – multivariable measurement

Fast and efficient commissioning – guided operating menus

High plant availability – self-diagnostics and error monitoring

Automatic recovery of data for servicing

Videos

Predecessor

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

-

-

Technical Information (TI)

Proline t-mass T 150 Technical Information

English version - 12/2013

Thermal mass flowmeter

EN 18/12/2013Language:

English

Version:

18/12/2013

File size:

1.2 MB

File name:

TI01127DEN_0113.pdf

-

-

-

Technical Information (TI)

Proline t-mass T 150 Technical Information

Thermal mass flowmeter

EN 18/12/2013Language:

English

Version:

18/12/2013

File size:

1.2 MB

File name:

TI01127DEN_0113.pdf

-

-

-

Operating Instruction (BA)

Proline t-mass T 150 HART Operating Instructions

Thermal mass flowmeter

EN 18/12/2013Language:

English

Version:

18/12/2013

File size:

3.4 MB

File name:

BA01260DEN_0113.pdf

-

-

-

Device Parameter (GP)

Proline t-mass T 150 HART Description of Device Parameters

Thermal Mass Flowmeter

EN 04/04/2016Language:

English

Version:

04/04/2016

File size:

1.5 MB

File name:

GP01032DEN_0115.pdf

-

-

-

Short Instruction (KA)

Proline t-mass T 150 Brief Operating Instructions

Thermal mass flowmeter

EN 18/12/2013Language:

English

Version:

18/12/2013

File size:

1.3 MB

File name:

KA01155DEN_0113.pdf

-

-

-

Installation Instructions (EA)

Safety Instructions for Spare Parts Installation Instructions

Flowmeter

EN 01/03/201828/11/201325/04/2013Language:

English

Version:

01/03/2018

File size:

139.5 KB

File name:

EA01051DA2_0318.pdf

-

-

-

Installation Instructions (EA)

Replacing the display module Installation Instructions

Promag 200, Promass 200, Prosonic Flow 200, Prowirl 200, t-mass 150,

Levelflex FMP5x, Micropilot FMR5x, Micropilot FMR6x, Remote dis

play FHX50EN 01/09/201701/02/201724/11/201528/11/201306/04/2012Language:

English

Version:

01/09/2017

File size:

562.2 KB

File name:

EA00102DA2_1817.pdf

-

-

-

Installation Instructions (EA)

Activating application packages

Promag 100, 200, 400, Promass 100, 200, Prosonic Flow 100, 200, Prowirl

200, t-mass 150EN 03/03/202015/02/2019Language:

English

Version:

03/03/2020

File size:

406.9 KB

File name:

EA01249DA2_0220.pdf

-

-

-

Installation Instructions (EA)

Hot tap

t-mass T 150

EN 01/04/202201/06/201715/05/2014Language:

English

Version:

01/04/2022

File size:

1.5 MB

File name:

EA01105DA2_0322-00.pdf

-

-

-

Installation Instructions (EA)

Cold tap, atmospheric pressure

t-mass 65I, t-mass B 150, t-mass T 150, t-mass I 300, t-mass I

500-digitalEN 31/07/202001/10/201804/10/2016Language:

English

Version:

31/07/2020

File size:

241.1 KB

File name:

EA01136DA2_0320.pdf

-

-

-

Installation Instructions (EA)

Replacing small parts Installation Instructions

t-mass A, B, T 150

EN 01/10/201823/06/201504/03/201424/04/2012Language:

English

Version:

01/10/2018

File size:

528.1 KB

File name:

EA00111DA2_0418.pdf

-

%20-%20CS01637X.jpg)